Overhead Rate Meaning, Formula, Calculations, Uses, Examples

The third step is to compute the predetermined overhead rate by dividing the estimated total manufacturing overhead costs by the estimated total amount of cost driver or activity base. Common activity bases used in the calculation include direct labor costs, direct labor hours, or machine hours. The predetermined overhead rate is the estimated cost of manufacturing a product.

1 Calculate Predetermined Overhead and Total Cost under the Traditional Allocation Method

Until now, you have learned to apply overhead to production based on a predetermined overhead rate typically using an activity base. An activity base is considered to be a primary driver of overhead costs, and traditionally, direct labor hours or machine hours were used for it. For example, a production facility that is fairly labor intensive would likely determine that the more labor hours worked, the higher the overhead will be. As a result, management would likely view labor hours as the activity base when applying overhead costs. Further, the company uses direct labor hours to assign manufacturing overhead costs to products.

- To account for these changes in technology and production, many organizations today have adopted an overhead allocation method known as activity-based costing (ABC).

- A pre-determined overhead rate is the rate used to apply manufacturing overhead to work-in-process inventory.

- The overhead rate has limitations when applying it to companies that have few overhead costs or when their costs are mostly tied to production.

- The allocation base includes direct labor costs, direct labor dollars, or the number of machine-hours.

- The estimated or budgeted overhead is the amount of overhead determined during the budgeting process and consists of manufacturing costs but, as you have learned, excludes direct materials and direct labor.

- The allocation of overhead to the cost of the product is also recognized in a systematic and rational manner.

- This rate is frequently used to assist in closing the books more quickly, since it avoids the compilation of actual manufacturing overhead costs as part of the period-end closing process.

Formula for Predetermined Overhead Rate

As explained previously, the overhead is allocated to the individual jobs at the predetermined overhead rate of $2.50 per direct labor dollar when the jobs are complete. When Job MAC001 is completed, overhead is $165, computed as $2.50 times the $66 of direct labor, with the total job cost of $931, which includes $700 for direct materials, $66 for direct labor, and $165 for manufacturing overhead. So, if you wanted to determine the indirect costs for a week, you would total up your weekly indirect or overhead costs. You would then take the measurement of what goes into production for the same period.

Concerns Surrounding Predetermined Overhead Rates

- The predetermined overhead rate calculation shown in the example above is known as the single predetermined overhead rate or plant-wide overhead rate.

- Let us take the example of ort GHJ Ltd which has prepared the budget for next year.

- The concept of predetermined overhead rate is very important because it is used most of the enterprises as it enables them to estimate the approximate total cost of each job.

- This can result in abnormal losses as well and unexpected expenses being incurred.

- For example, a production facility that is fairly labor intensive would likely determine that the more labor hours worked, the higher the overhead will be.

- Larger organizations may employ a different predetermined overhead rate in each production department, which tends to improve the accuracy of overhead application by employing a higher level of precision.

Estimating overhead costs is difficult because many costs fluctuate significantly from when the overhead allocation rate is established to when its actual application occurs during the production process. You can envision the potential problems in creating an overhead allocation rate within these circumstances. If an actual rate is computed monthly or quarterly, seasonal factors in overhead costs or in the activity base can produce fluctuations in the overhead rate. For example, the costs of heating and cooling a factory in Illinois will be highest in the winter and summer months and lowest in the spring and fall. If the overhead rate is recomputed at the end of each month or each quarter based on actual costs and activity, the overhead rate would go up in the winter and summer and down in the spring and fall.

What is Absorption Costing? – TechPresident

What is Absorption Costing?.

Posted: Thu, 25 Apr 2024 06:54:10 GMT [source]

Great! The Financial Professional Will Get Back To You Soon.

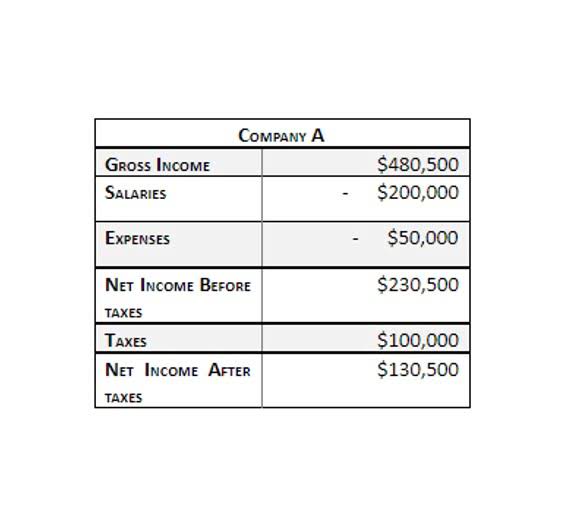

With $2.00 of overhead per direct hour, the Solo product is estimated to have $700,000 of overhead applied. When the $700,000 of overhead applied is divided by the estimated production of 140,000 units of the Solo product, the estimated overhead per product for the Solo product is $5.00 per unit. The computation of the overhead cost per unit for all of the products is shown in Figure 6.4.

This rate is frequently used to assist in closing the books more quickly, since it avoids the compilation of actual manufacturing overhead costs as part of the period-end closing process. However, the difference between the actual and estimated amounts of overhead must be reconciled at least at the end of each fiscal year. You and the other managers at XYZ, Inc. have reviewed the historical overhead rates within your division and found that there is a link between the amount spent on materials to make your product and the total overhead.

- At Finance Strategists, we partner with financial experts to ensure the accuracy of our financial content.

- To calculate a predetermined overhead rate, divide the manufacturing overhead cost by the units of allocation.

- There are some things that are needed in order to figure out an accurate predetermined overhead rate.

- Finally, you would divide the indirect costs by the allocation measure to achieve how much in overhead costs for every dollar spent on direct labor for the week.

- As explained previously, the overhead is allocated to the individual jobs at the predetermined overhead rate of $2.50 per direct labor dollar when the jobs are complete.

- In these situations, a direct cost (labor) has been replaced by an overhead cost (e.g., depreciation on equipment).

This concept is important because these costs must be estimated in order to properly provide accurate prices to future customers. If overhead is overestimated, then prices will be too high and that can cause customers to seek their products or services from other companies (most likely their competitors). If overhead is underestimated, then the company may set their prices too low and not earn profits or experience a loss. The use of historical information to derive the amount of manufacturing overhead may not apply if there is a sudden spike or decline in these costs. This is a particular concern in highly competitive industries where production rates may vary dramatically, based on the popularity of the latest round of product releases. If sales and production decisions are being made based in part on the predetermined overhead rate, and the rate is inaccurate, then so too will be the decisions.

Predetermined Overhead Rate: Formula, Applications & Limitations

For example, overhead costs may be applied at a set rate based on the number of machine hours or labor hours required for the product. For the last three years, your team found that the total overhead rate has been between 1.7 and 1.8 times higher than the direct materials rate. As such, you and your peers have agreed to set the predetermined overhead rate at 175% of the direct materials rate. There are some things that are needed in order to figure out an accurate predetermined overhead rate.

Formula to Calculate POHR.

Based on the manufacturing process, it is also easy to determine the direct labor cost. But determining the exact overhead costs is not easy, as the cost of electricity needed to dry, crush, and roast the nuts changes depending on the moisture content of the nuts upon arrival. Larger organizations may employ a different predetermined overhead rate in each production department, which tends to improve the accuracy of overhead application by employing a higher level of precision. However, the use of multiple predetermined overhead rates also increases the amount of required accounting labor. In order to find the overhead rate we will use the same basis that we have chosen by multiplying this basis by the calculated rate. For example, if we choose the labor hours to be the basis then we will multiply the rate by the direct labor hours in each task during the manufacturing process.

Leave a Reply